IGEP of Planning and Evaluation

The green power hydrogen production system mainly includes:

- Strong grid-connected mode and weak grid-connected system

- AC off-grid hydrogen production mode and DC off-grid hydrogen production system

- Advantages of the solution: Flexibility, safety, efficiency, and intelligence. Through this system, it is possible to produce green hydrogen more safely and at a lower cost.

System Architecture:

- Energy Management System (EMS)

- Hydrogen Production Control System (DCS)

- Hydrogen Production Power Supply

- Electrolyzer

- Separation and Purification

- Auxiliary Devices

For green energy project investment and development, Hyjade (IGEP) delivers intelligent, high-efficiency solutions:

- Solar, Energy Storage, and Charging System

- Wind, Solar, and Hydropower-Based Green Hydrogen, Ammonia, and Methanol Production System

- Hydrogen Storage and Hydrogen Fuel Cell Power Generation System

- Multi-Energy Complementary Integrated Energy System

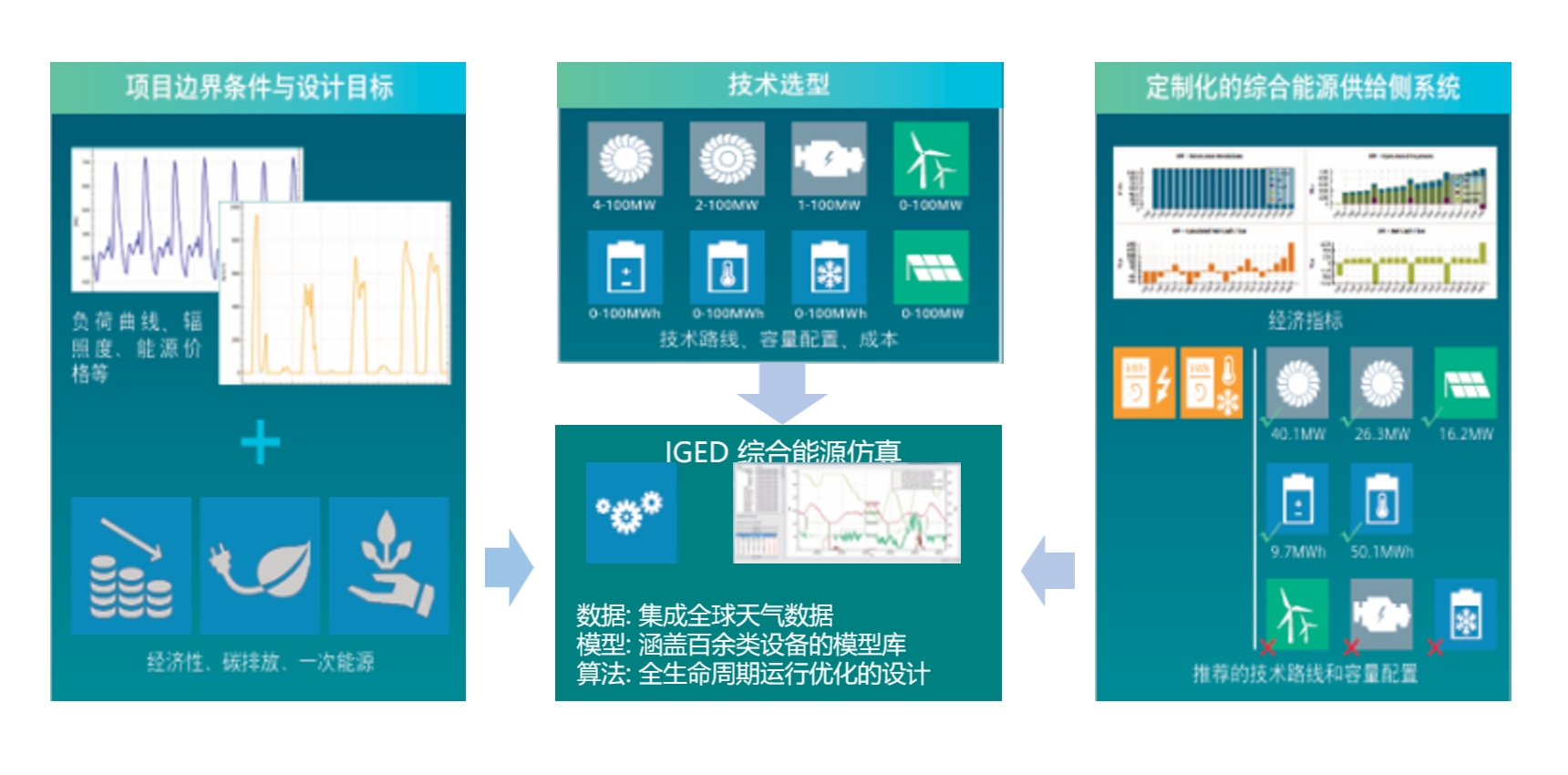

The Intelligent Green Energy Platform (IGEP) leverages local advantageous resources and market environments to optimally select from multiple technical routes, clearly mapping energy conversion pathways and carbon emissions. It balances economic evaluation with carbon reduction efficacy, overcoming technical challenges in project planning and design to simplify complex project design.

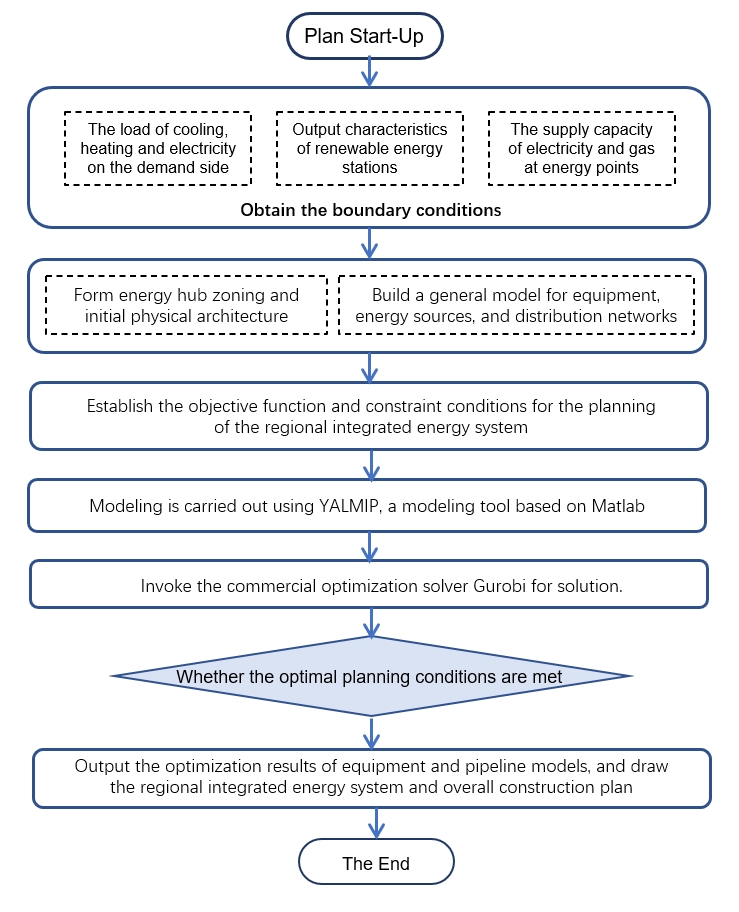

IGEP is a specialized simulation tool designed for integrated energy and microgrid systems. The software features a robust and comprehensive model library that encompasses nearly all energy equipment and conversion technologies involved in distributed energy systems. For specific projects, designers can conduct thorough research on local resource endowments, commodity prices, load types and demands, weather environment data, user requirements, etc., to determine project boundary conditions. Based on certain planning and design objectives (such as optimizing overall economics or minimizing energy consumption and carbon emissions), optimal design methods are used to derive parameters such as technology selections and equipment capacities suitable for the specific project.

The IGED platform employs an economic dispatch algorithm (planning solver) based on day-ahead load and generation forecasting to perform optimization calculations for the system over 8,760 hours annually or throughout its full lifecycle, comprehensively evaluating the economic impact of optimized operations on the project. Calculation step sizes can be set to 1/5/15/30/60 minutes as required. The planning method of day-ahead forecast-based economic dispatch integrates future system operation scenarios—particularly the coupled operation of multi-energy complementarity—into the planning process in advance. As an operation-optimized planning approach, it enables a comprehensive assessment of the project’s lifecycle costs and carbon emissions.